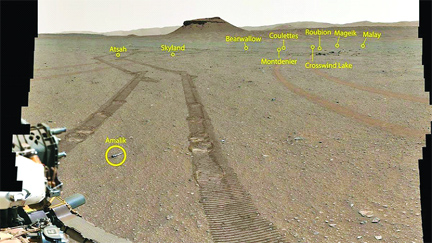

Nearly two years after it was launched to the Red Planet, the Perseverance rover has done more than just science. It has now constructed a sample depot on the planet that will be used by future missions to return samples to Earth. The rover has beamed back a portrait of the 10 backup sample tubes. The rover has sent a panoramic view of the recently completed sample depot, which is a big milestone for the mission and humanity’s first collection of samples on another planet. The image has been made from 368 images that were sent to Earth.

Nasa said that eight of those tubes are filled with rock and regolith from Mars, while one is an atmospheric sample and one is a “witness” tube. The rover used its Mastcam-Z camera on the top of its head to capture the images that were then stitched together to form the panoramic view.

Nasa said that the depot represents a backup collection of samples that could be recovered in the future by the Mars Sample Return campaign, a joint effort between Nasa and ESA (European Space Agency) that aims to bring Mars samples to Earth for closer study.

Perseverance built the depot at “Three Forks,” a location within Jezero Crater. Billions of years ago, a river flowed into the crater, carrying sediment that formed a steep, fan-shaped delta that the rover will drive up in the months ahead. Astrobiologists suspect that while the Martian surface is now cold, dry, and generally inhospitable to life, ancient Mars was likely similar to Earth – and could have supported microbial life if any ever formed on the Red Planet. The work to build a depot on another world was not easy and the first critical requirement was finding a level, rock-free stretch of terrain which has room for each tube to be deposited. The next target was to figure out exactly where and how to deploy the tubes within that location.

While Perseverance has dropped these sample tubes, work is underway on Earth to ready for the retrieving mission that will launch to Mars, pick up these samples and return home.

Source: India Today